A single-story bungalow could take a few months to build, but this printer can complete the project in less than four days.

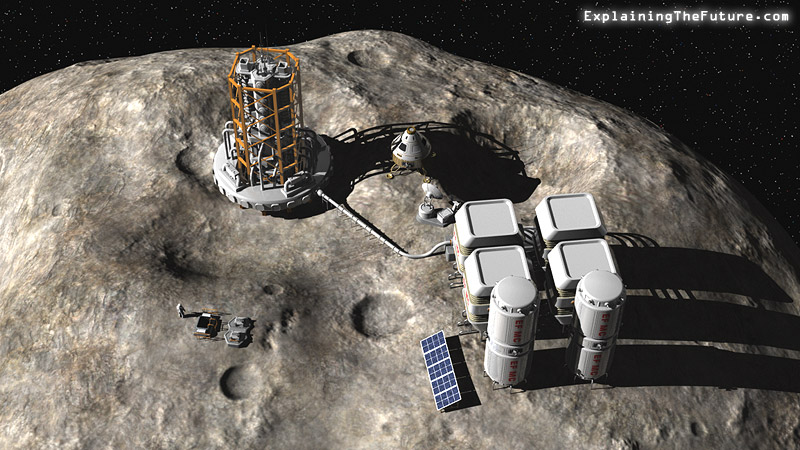

As tenants move into 3D-printed houses for the first time, these gray and ribbed texture — are even piquing the interest of NASA, which funded a $57 million project to develop tech for moon side 3D-printed infrastructure. As the University of Maine smashed the world record for the largest 3D printer, the thermoplastic polymer printer can print objects as large as 96 feet long by 32 feet wide by 18 feet high — consuming 500 pounds of material per hour. Highly customizable and free of form, construction 3D printing is a new-age tech on the verge of market disruption, holding the potential to mass produce housing. If you wanted to know how much it would cost it would be about $10,000 to $400,000 on average, but pricing can vary based on the house’s location, size, amenities and materials used.

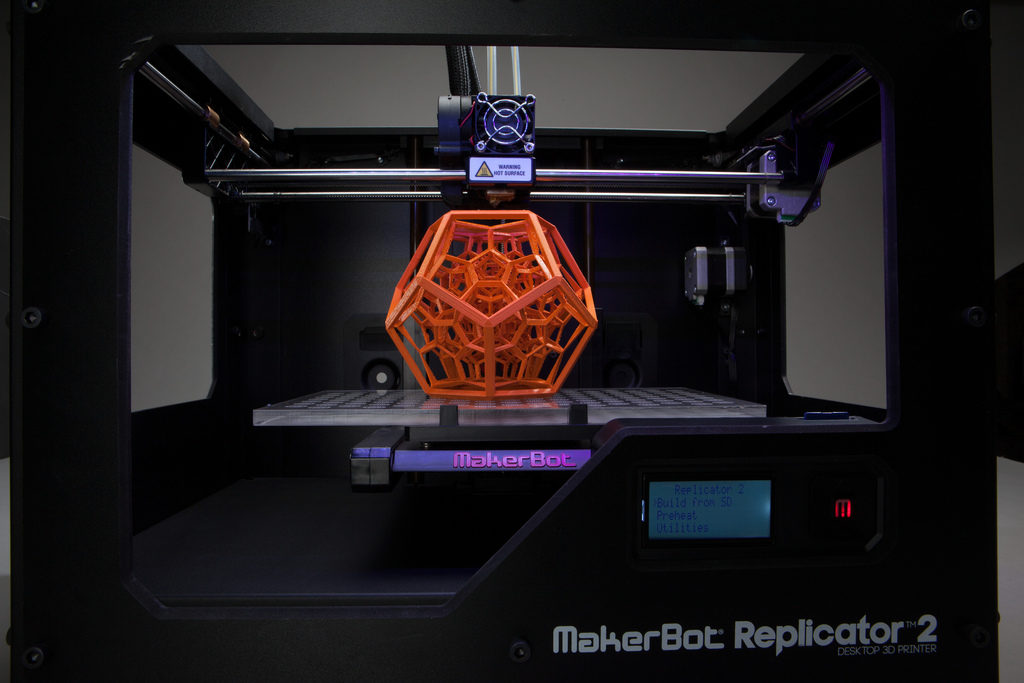

What is 3D Printing?

3D printing is a process in which a digital model is turned into a tangible, solid, three-dimensional object, usually by laying down many successive, thin layers of a material. 3D printing has become popular so quickly because it makes manufacturing accessible to more people than ever before. This is partly due to the price but also the small size of the printers compared to traditional manufacturing. First a computer system is used in order to make the blueprints for printing. Then the blueprints are uploaded to the printer and it begins printing, usually finishing in 30 minutes-12 hours.

What Can We Do With This Printer?

Its applications range from industries to national security — meaning, if they need to build ships fast, they have the technology to do so. Though, typically, it takes years to build military ships, in WWII, the US manufactured the Liberty ships in 42 days. These large-scale 3D printers could feasibly meet that speed and maybe surpass it if needed. It can switch functionalities between “additive manufacturing, subtractive manufacturing, continuous tap layup, and robotic arm operations.” It’s both a computer and a manufacturer that the Office of the Secretary of Defense and US Army Corps of Engineers helped to design and build. The FoF 1.0 stands to revolutionize a variety of industries. That includes affordable housing, public works such as bridge construction, and ocean and wind energy. And it’s all recyclable, which means that it can be grinded down and reused again and again until products reach good standards.

Related Stories

https://realestate.usnews.com/real-estate/articles/are-3d-printed-homes-the-future-of-housing

https://builtin.com/articles/3d-printed-house