All About Wire

Did you know many wires are made out of copper?

What about wires?

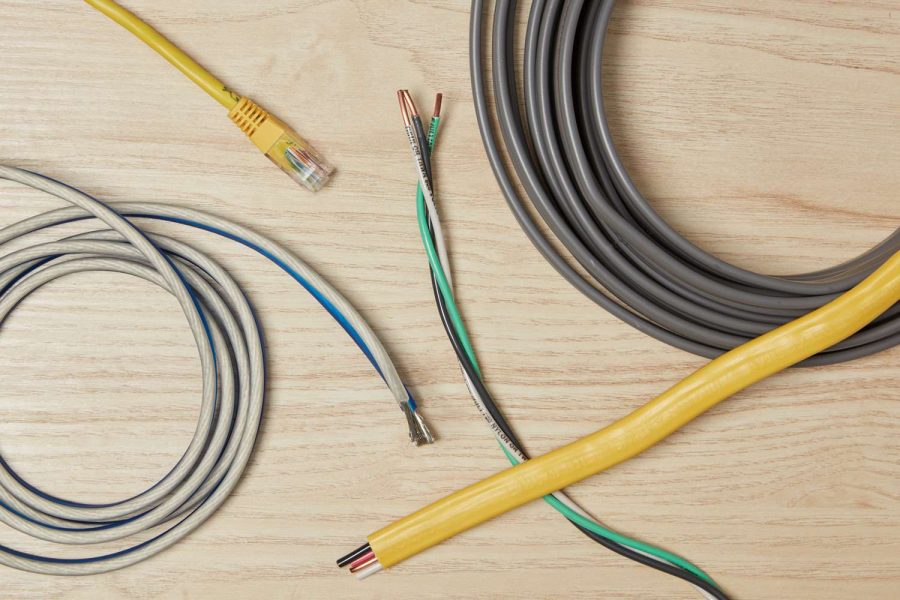

Think of all the cables you use every day. Cables are an integral part of our lives, even if we don’t always think about them. Wires, guitar strings, and paper clips are just a few examples of electrical wires. Even the Internet consists of many computers connected by wires. Cables are so common in our lives that we don’t always think about them.

What materials are wires made of?

Wire is metal. Metals used include steel, copper, aluminum, and silver. These materials are used only for manufacturing due to their properties. Metals have high melting points and are usually solid at room temperature. They are also malleable. This makes it easy to stretch. After all, metals are excellent conductors of heat and electricity. Therefore, electricity and heat can pass through without problems.

What is the process?

First, a piece of steel called a billet is heated to approximately 2000°C. This makes it easier to change the shape. The hot billet passes through a series of rolling mills that convert the metal into bars with diameters from 1 to 4 cm. The rod is then formed into a coil. Take the coil out and let it cool. Each coil weighs approximately 700-900 kg.

The surface of the spool may rust and become dirty during storage. This should be cleaned before the next step. To clean, soak the coil in a warm water solution containing chemicals that remove surface dirt. The bar is then fed through a series of lubricated dies. A lubricant is a substance that makes something slippery. Oil is often used as a lubricant.

A die is a tool used to press, cut, or shape materials. Here the die reduces the large diameter of the rod to a smaller diameter wire. The wire is elastic enough to withstand the forces of this process. Materials with low ductility, such as glass, shatter. A thin wire is formed at the end. Manufactured by the Blachford Chemical Group*, this lubricant reduces friction and forms a barrier as the wire passes through the die. Lubricants speed up the process and extend the life of the mold. In steel wire drawing, the lubricant is powder. Load the powder into the die box and feed the wire first through the powder and then through the die. The faces of the cube have cones. As the diameter decreases, the wire is coated with a lubricant. Cleaning may be required before processing into the final product.

This process can generate dust. This dust can pose a dust explosion hazard. For this reason, dust prevention is important in wire drawing.