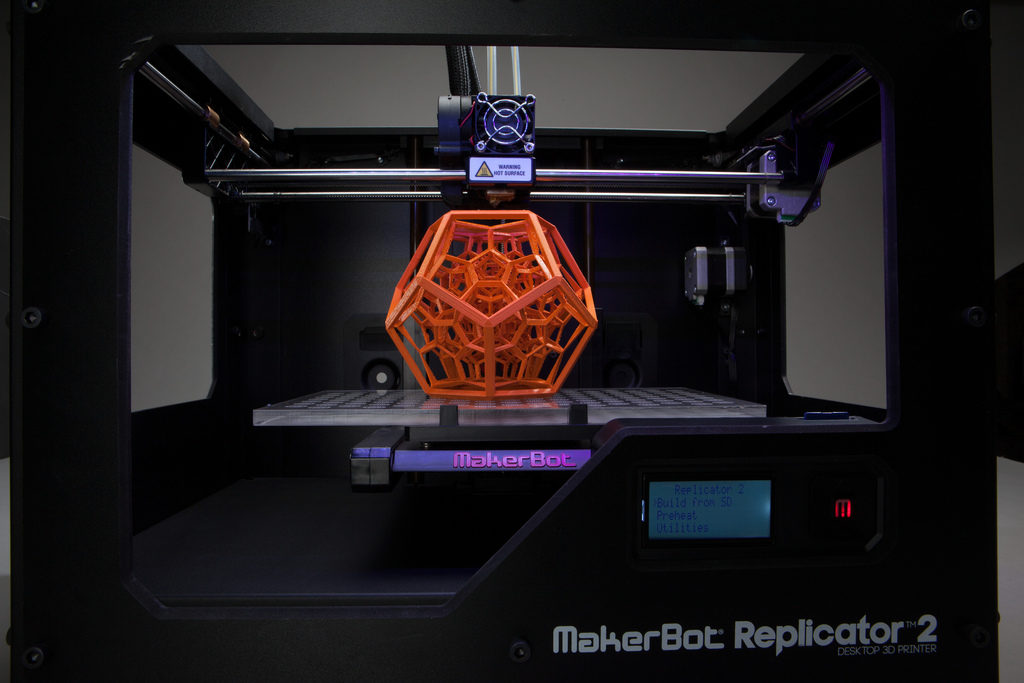

3D Printing Recycled Plastic

The 3D printing recycled plastic process involves breaking down plastic into smaller pieces, melting it and then using that material as the ink for the 3D printer.People are experimenting with this to make all sorts of things,from small items like phone cases to larger objects. Its a way to reuse plastic that would otherwise end up in a landfill, and it could possibly reduce the need for new plastic production. There are challenges like ensuring the recycled plastic is clean and consistent. (;

Local 3D Printing

3D printing has been changing things around, especially with some of the local maker spaces and small businesses getting into additive manufacturing. Basically what they’re offering is a way for individuals and companies to test out designs, make custom parts, and do smaller production runs. The fact that this tech is becoming more accessible in our communities is helping to spark new ideas and giving both consumers and businesses more chances to try out new things.

Lightweight Design

3D printing is changing its lightweight design by allowing the creation of complex, hollow parts that are both strong and light. A key advantage is the ability to design internal lattice or honeycomb structures, which provide strength while using less material. Studies show that you can achieve significant weight reduction this way, which is helpful in fields like aerospace and automotive.Its not just about making things lighter,it’s about designing smarter parts that can handle stress without extra bulk,opening doors for new product possibilities.

RELATED STORIES

https://www.3devo.com/blog/sustainable-3d-printing-create-use-recycled-filament

https://www.3ds.com/make/solutions/blog/3d-printing-and-recycled-materials

https://www.sciencedirect.com/science/article/pii/S0264127523009747

https://vanplestik.nl/en/welcome/

TAKE ACTION

https://www.instructables.com/Recycle-Plastic-Into-3D-Printer-Filament-at-Home/