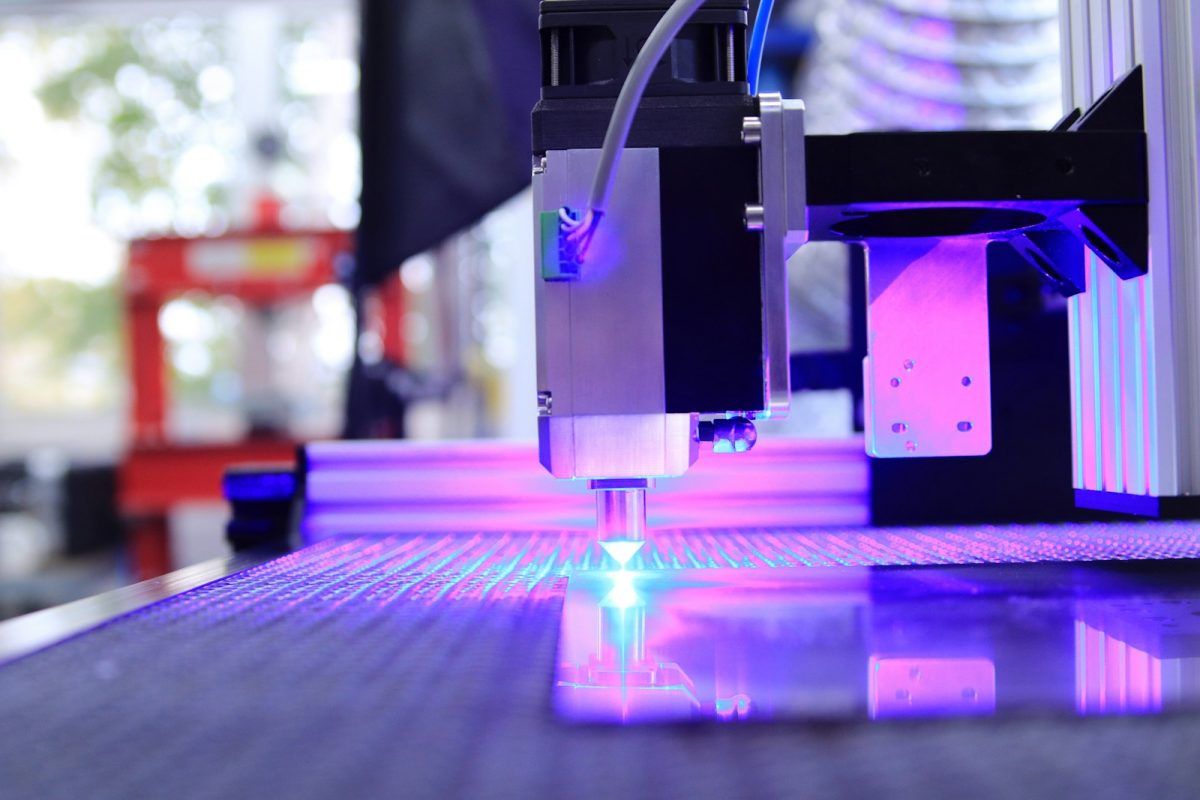

The answer, according to NRCC researchers, is to blur the laser on the 3D printer. It seems counterintuitive, but NRCC researchers have come up with a new method to create better-quality 3d-printed optics.

This new method – Blurred Tomography – improved 3D-printing optics and drastically reduced printing time. The optics produced were at least equivalent to commercially available optics. They could be printed in half an hour or less.

“We intentionally blurring the light beams of this method to produce precision optical components,” Daniel Webber of the National Research Council on Cosmetology (NRCC) said.

“Optically smooth surfaces can be produced through this method.” Webber added that Tomographic Volumetric Additive Manufacturing (VAM) is a “cost-effective and rapid prototyping method for optical components” due to the cost-effectiveness of the Tomographic 3D Printer and materials used.

“The inherent freeform of Tomographic 3D Printing could also allow optical designers to streamline designs by replacing several standard optics by printed optics with complex shapes,” Webber said. “This method allows for the printing of an entire part at once without any support structures.”

Current tomographic methods cannot print imaging quality lenses directly because of striations that cause tiny ridges on the part’s surface. This is not good for optical components. Post-processing can create smooth surfaces, but it takes more time and complexity, which defeats the benefits of rapid prototyping with tomographic printing.

“Manufacturing optical components is expensive because of the high technical requirements for a working lens and the complicated and time-consuming manufacturing process,” Dr. Webber said. “Blurred tomography allows for low-cost freeform designs.”

“As this technology develops, it could enable much faster prototyping of new optical devices for commercial manufacturers and garage inventors alike,” he added. The researchers first tested the effectiveness of their new method by producing a basic plano convex lens. They found that the news lens had only a form error of a few microns, and the surface roughness was less than one nanometre.

Related Stories

- https://www.sciencedaily.com/releases/2024/05/240509110855.htm

- https://www.voxelmatters.com/3d-printed-micro-optics-on-fibers-create-stable-hybrid-lasers/

- https://www.cloudynights.com/topic/821796-possible-to-3d-print-better-baffles-than-you-could-make-otherwise/

- https://www.photonics.com/Articles/3D_Printed_Micro-optics_Embed_into_a_Durable/a69544

- https://budgetlightforum.com/t/3d-printed-optics/55591

Take Action