Railroad Switches

Getting Trains on the Right Tracks

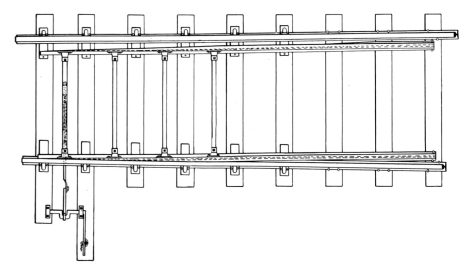

Railroad track switch. Source: Wikipedia (https://en.wikipedia.org/wiki/Railroad_switch)

Railroad track switches are used on rail systems. They change the railroad track’s direction from one track to another. When trains go over the switch, depending on it’s alignment, the train goes to one track or the other. Trains cannot steer, like road vehicles, so railroad switches are key to getting trains to their correct destinations on time.

How do railroad switches work?

Railroad switches can be operated by two means: manually or electronically. Nevertheless, the railroad track switch is of the same design. Two switchblades which make the train’s wheels go from one track to another are the main part of the switch. When the blades are pushed in one direction, the train will diverge to another track. When the blades stay the same position, the train stays in its current track.

Both blades, at one end are connected to a rod, allowing flexibility of the switchblades. The rod

connects to linkages that connect to a switch lever or an electronic switch operating motor. The other ends of the switchblades are allowed to pivot when the switchblades change direction. Manually operated switches are controlled by a lever and electronically operated switches are controlled by a switch operating motor. It’s controlled from a control center.

The outer rails of the switch, known as the stock rails, at the meeting point of both tracks, house the guard rails, placed in the inside of the switch. Stock rails are rails of the railroad track that don’t make up the moving or other parts of the switch. The inner stock rails of the switch at the meeting point of both tracks have a gap in them, with a guide called the frog to correctly guide the train wheels to the track the train is being switched to, without derailment. Both guard rail and switch frog play a key role to prevent the train from derailing while it crosses the switch.

Maintenance and Safety

Railroad switches are a vital part of railroad infrastructure. They need to be frequently maintained and in good condition. Moving parts of a switch are the most vulnerable for wear and tear. If a switch isn’t properly maintained, then it can malfunction. Trains have been derailed due to improperly maintained or malfunctioning switches. Switches which are misaligned, set to the wrong track, are dangerous, as there can be a potential for a collision between a train which was sent to the wrong track by a misaligned switch and a train which was on the track the train was sent to by that misaligned switch. All switches must be set to the right direction the train needs to travel to ensure the safety of the rail network and the train’s occupants.

In cold conditions, the switch’s moving parts can be prone to freezing, or covered by snow. This can hamper the

proper operation of a switch. To combat this problem, there are heaters around the moving parts of the switch, to prevent them from freezing or being covered by accumulating snow, which will prevent the moving switch parts from moving. This method comes with it’s problems, though. The heaters need time to heat up to melt snow and/or ice, and on frequently used switches, there could be not enough time to melt the ice before another train comes.

Railroad switches are vital for ensuring that a railroad runs efficiently, and safely. The frequent maintenance of railroad switches allows for the safe travel of trains, in addition to getting their trains to their correct destinations.

Related Stories

https://en.wikipedia.org/wiki/Railroad_switch

https://en.wikipedia.org/wiki/Railroad_switch#Operation_in_cold_conditions

https://econstructioncareers.com/news-insight/how-trains-change-track

http://www.railway-fasteners.com/news/what-is-the-railway-switch.html

http://www.rail-fastener.com/types-of-rail-switches.html

Take Action

You have a chance to see railroad switches if you ride a metro system frequently, like on the Washington Metro. When waiting for your next train, try to locate a switch near the station, and you may get a glimpse of it changing direction!