Recently, developments in 3D printing technology have led to a new method of creating three dimensional objects. Conventional 3D printers utilize color plastic filaments, which are melted and dispensed, forming the desired object layer by layer. Normally, this method will take hours, and potentially even days, to create a single object. Additionally, complicated builds require supports to be built, so that the hot plastic will not succumb to gravity.

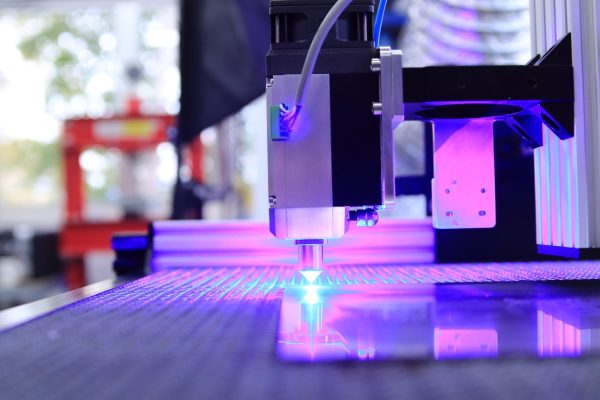

Nicknamed “The Replicator,” the new 3D printer makes objects out of a photosensitive resin. After creating a computer model of the desired item, an ordinary projector is hooked up to the computer. The projector is aimed at a rotating cylinder filled with the photosensitive resin. As light is shown on the resin, oxygen in the resin is depleted, changing the resin into a solid. The entire process takes between 30 to 120 seconds. However, The Replicator is currently only capable of printing objects 4 inches in diameter.

This new way to 3D print objects is far more advanced than any before it. The Replicator takes mere minutes to print objects, which is insanely fast compared to the hours or even days it takes for a conventional 3D printer to create objects. Also, the printer can create more complex, intricate objects. Another advantage of these new printers is the fact that they do not require supports. One of the most impressive features about this 3D printer is the quality of the objects created. With most printers, the layer by layer method leads to a stair-step like appearance, which is not true with light 3D printers. Finally, 3D printers that use light can encase objects with layers of new material, something that normal printers struggle to do.

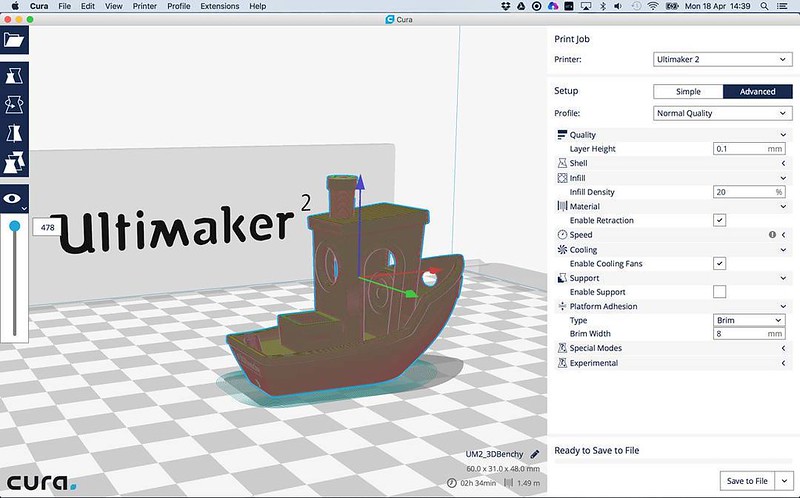

3D printers incorporate many aspects of engineering. The printer itself is a combination of many parts, but the real engineering in a 3D printer is the coding. In order to print an object, computer programs must be used to create a model of the desired object to be printed. Then, other programs have to be used to format that model in a way that allows the printer to understand what it must do. In the case of these “Replicator” 3D printers, the projector has to be told in what way it must project light to create the desired object.

Related Links:

- https://newatlas.com/resin-light-3d-printing/58301/

- https://www.3dnatives.com/en/3d-printing-with-light-160120194/

- https://interestingengineering.com/fascinating-new-3d-printer-using-rays-of-light-has-the-potential-to-change-product-design

- https://www.firstpost.com/tech/science/groundbreaking-new-3d-printer-the-replicator-uses-light-to-print-objects-in-resin-6030351.html

- https://techcrunch.com/2019/02/01/this-light-powered-3d-printer-materializes-objects-all-at-once/